Euratainer 1

Euratainer 1

Artikelnummer: 10184

Specifications

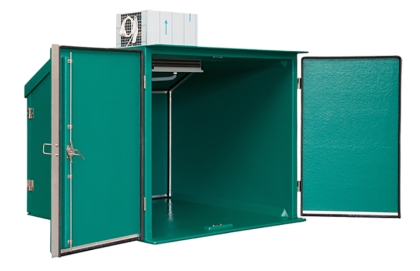

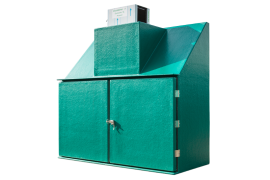

- 85 x 90 x 129 cm

- The Euratainer is constructed from durable polyester

- 85 kg

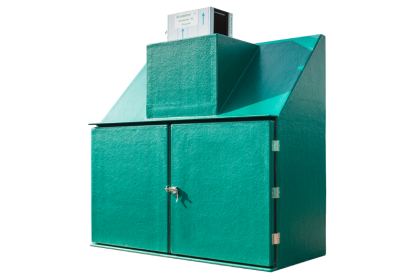

- Propane R-290 (CFC-free, halogen-free)

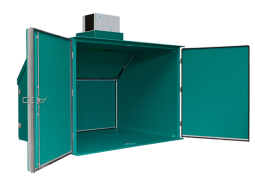

- Stainless steel evaporator as standard with durable TIG welds

- Fully wired, 230 V / 50 Hz (13A earthed plug)

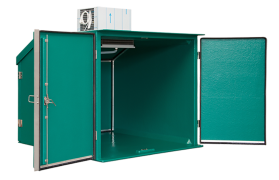

- One mini-container of 240 litres

Description

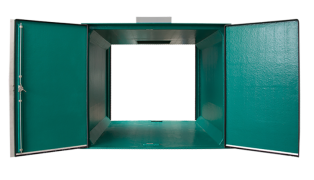

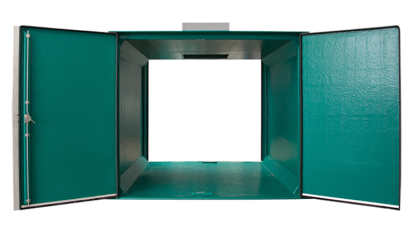

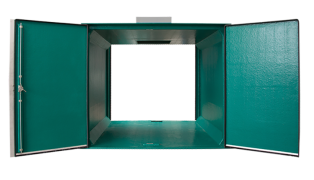

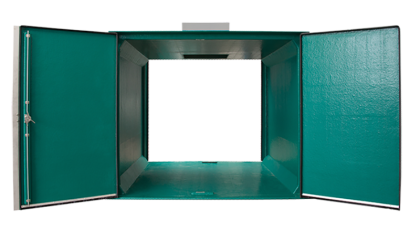

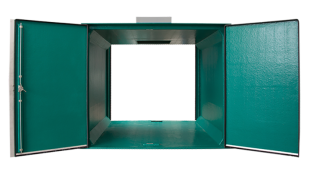

This Euratainer 1 cadaver refrigeration system is the classic product in our range: the predecessor of this model was the very first cadaver refrigerator on the market. The Euratainer 1 is ideal for companies that have a small amount of waste flow to deal with. It is our entry-level model that is also widely used in sectors other than the livestock industry (such as the catering industry and veterinary practices). Ideal for smaller companies looking for a solution for their cadaver storage or waste flow.

This cadaver refrigeration system comes complete with our RVS evaporator with TIG seam welds. These welds contain no ‘other raw materials’ such as tin or silver that can be sensitive to the aggressive gasses, such as ammonia, produced by cadavers. In short, our welded seams are also RVS.

The automatic thermostat incorporated in our refrigeration unit makes the Euratainer very easy to use. It is ready to plug-in. The thermostat ensures that the temperature is constantly held between 4 and 8 degrees.

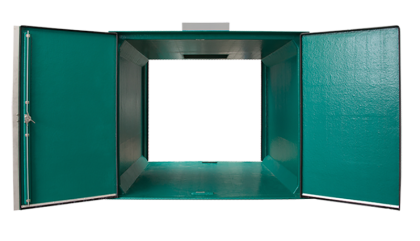

The outer casing is made of polyester with insulated walls (6 cm thick, with an insulation value of 0.323 W/m²K). The interior is completely seamless, which makes cleaning simple and means no waste residue can be left behind.

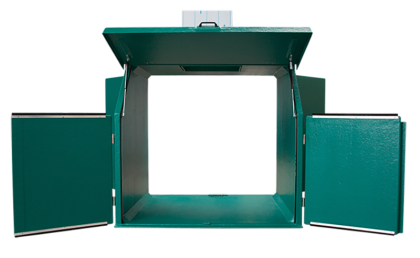

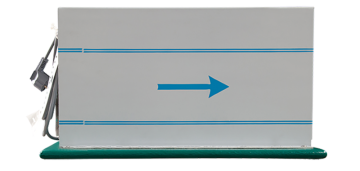

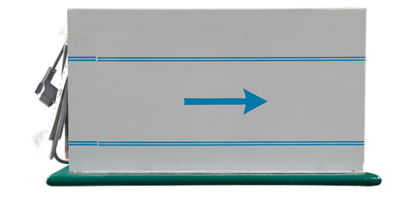

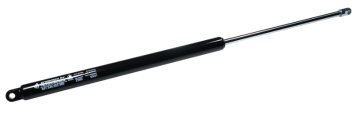

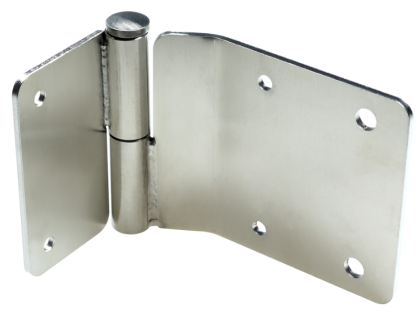

The loading door has gas pressure springs, which make it simple and ergonomic to use. This cadaver refrigerator has a removable front panel to facilitate unloading barrels or containers.

Euratainer 1